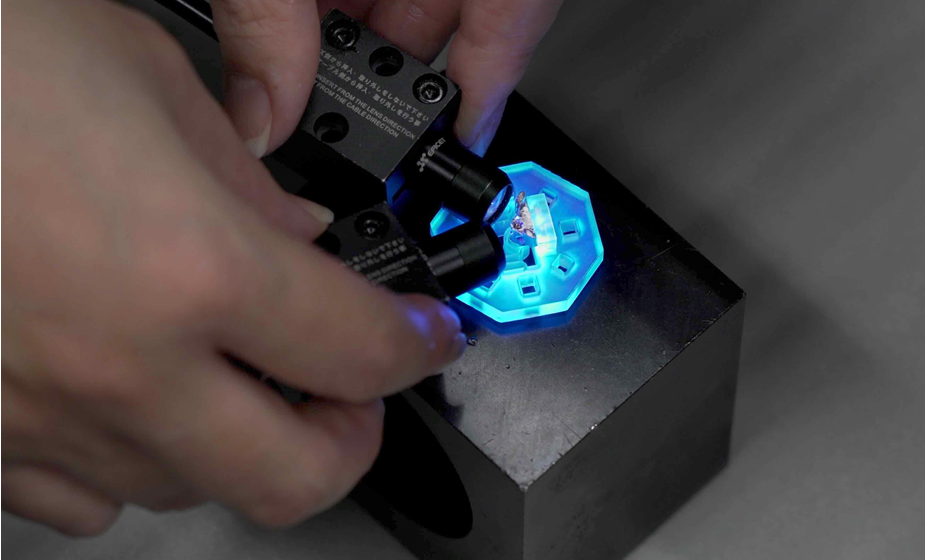

DS Audio produced a video showing the manufacturing process of a needle tip unit for an optical cartridge, including a guide on the screen that is displayed on the actual jig. The content of the video allows the viewer to understand at a glance how the tilt, angle, and position of the needle unit are controlled during the actual manufacturing process. DS Audio is the only company in the world that manufactures record needles using such a jig.

Unlike MM and MC cartridges that generate electrical signals through magnetic induction, DS Audio’s optical cartridges use an infrared LED and photodiodes (photo cells) to detect changes in light. As the needle moves through the record grooves, it causes a shading plate to oscillate, modulating the light received by the photodiodes. This method eliminates magnetic resistance, allowing for smoother needle movement and reduced moving mass.

The cartridge assembly starts with precision engineering of the LED, photodiodes, and the light-shading plate. These components

are integrated into a meticulously designed body, often milled from solid materials like aluminum to ensure stability and durability. The light-shading plate’s movement, influenced by the needle’s vibrations, is crucial for accurate signal detection.

The signal from the optical cartridge requires a dedicated equalizer, as the output characteristics differ from those of MM and MC cartridges. The equalizer powers the internal LED and adjusts the signal according to the specific needs of the optical system. This equalizer simplifies the RIAA correction circuit due to the flat amplitude proportional output of the optical cartridge.

Advantages of Optical Cartridges

- Reduced Moving Mass: The light shading plate is much lighter

Click the link below to see the process!

Recent Comments