In Service to Vinyl Playback: A 28 Hour Trip to Greece

Following the conclusion of the 2024 High End Munich Audio Show I took a quick 28 hour trip to Thessaloniki, Greece to spend time wetting my fingers in machine oil and engaging in extensive conversation with a master machinist who holds a PhD in Sound Synthesis and a Master’s Degree in Sonic Arts and Media Production. The topic of discussion over one very intensive day: the mechanical principles required to faithfully extract music from record groove walls.

In February 2014 Michael Fremer wrote an article on a hitherto neglected analog setup parameter that would be given the unfortunate name of “zenith error”, a rotation of the stylus about a vertical axis. Writing about the research performed by Wally Malewicz (founder of WAM Engineering and my mentor), Fremer’s article made it quite obvious that aligning the cantilever is – and had only ever been – simply a proxy for what actually mattered: the two groove-wall contact points on the stylus itself. Until then, we had always *unknowingly assumed* that a line drawn between the two points would be perpendicular to the vertical plane through the cantilever. Not so!

In February 2014 Michael Fremer wrote an article on a hitherto neglected analog setup parameter that would be given the unfortunate name of “zenith error”, a rotation of the stylus about a vertical axis. Writing about the research performed by Wally Malewicz (founder of WAM Engineering and my mentor), Fremer’s article made it quite obvious that aligning the cantilever is – and had only ever been – simply a proxy for what actually mattered: the two groove-wall contact points on the stylus itself. Until then, we had always *unknowingly assumed* that a line drawn between the two points would be perpendicular to the vertical plane through the cantilever. Not so!

The mechanical, electrical and sonic impact of stylus zenith error had not been studied in the journals over the decades. This was a challenge we decided to dive into with the help of Jeff Falk, a mechanical engineer with expertise in finite element analysis and Fred Stanke, a Stanford University EE PhD who spent his whole career in optics, sound propagation and computational analysis.

Next, we needed to prove that the electrical characteristics of zenith error would agree with our expectations. We acquired a 1 foot tall stack of various laboratory test records to help in this matter, many of them now quite “unobtanium” and highly respected by recording engineers.

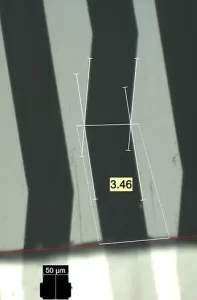

To our dismay, what we expected to find when analyzing zenith error electrically (by playing the test record and analyzing the distortion characteristics of the output) was often NOT what we ended up seeing. This confused and frustrated us for some time so we decided to look closely at the grooves under the microscope. That is where the mystery began to reveal itself.

To our dismay, what we expected to find when analyzing zenith error electrically (by playing the test record and analyzing the distortion characteristics of the output) was often NOT what we ended up seeing. This confused and frustrated us for some time so we decided to look closely at the grooves under the microscope. That is where the mystery began to reveal itself.We found frequent cutting e rrors on even the most vaunted test records. Cutting zenith errors as much as 5° weren’t tough to find. This kind of mechanical cutting error is fatal if we are expecting to trust a record to help us know our distortion at time of playback!

rrors on even the most vaunted test records. Cutting zenith errors as much as 5° weren’t tough to find. This kind of mechanical cutting error is fatal if we are expecting to trust a record to help us know our distortion at time of playback!

We then asked a very well known recording engineer to send us a few of his used cutting styli. Cutting styli are designed to have each cutting edge be 45° from the shank centerline. To our amazement, the very first one we measured was 43°/47°. This cutting stylus guarantees crosstalk cut right into the grooves!

Recent Comments